- Fuel Tankers

- SF3330 AL

- SF3330_3A_10, 30 m3, 3 compartments, fifth-wheel 1150

- SF3330_5A_13, 30 m3, 5 compartments, fifth-wheel 1150

- SF3330_5A_04, 30 m3, 5 compartments, fifth-wheel 1150

- SF3330_5A_03, 30 m3, 5 compartments, fifth-wheel 1250

- SF3330_3A_08, 30 m3, 3 compartments, fifth-wheel 1250

- SF3330_5A_14, 30 m3, 5 compartments, fifth-wheel 1250

- SF3330_3A_07, 30 m3, 3 compartments, fifth-wheel 1250

- SF3330_3A_05, 30 m3, 3 compartments, fifth-wheel 1250

- SF3330_3A_04, 30 m3, 3 compartments, fifth-wheel 1250

- SF3330_3A_03, 30 m3, 3 compartments, fifth-wheel 1250

- SF3330_3A_02, 30 m3, 3 compartments, fifth-wheel 1250

- SF3330_3A_01, 30 m3, 3 compartments, fifth-wheel 1250

- SF3330_3A_06, 30 m3, 3 compartments, fifth-wheel 1250

- SF3330_4A_02, 30 m3, 4 compartments, fifth-wheel 1250

- SF3330_4A_03, 30 m3, 4 compartments, fifth-wheel 1200

- SF3330_4A_11, 30 m3, 4 compartments, fifth-wheel 1250

- SF3330_5A_11, 30 m3, 5 compartments, fifth-wheel 1250

- SF3330_5A_12, 30 m3, 5 compartments, fifth-wheel 1250

- SF3330 BG

- SF3330.4S_110, fifth-wheel 1250, 4 compartments

- SF3330.4S_113, fifth-wheel 1250, 4 compartments

- SF3330.3S_109, fifth-wheel 1250, 3 compartments

- SF3330.3A_101, fifth-wheel 1250, 3 compartments

- SF3330.4S_108, 30 m3, 4 compartments, fifth-wheel 1250

- SF3330.4S_103, 29 m3, 4 compartments, fifth-wheel 1250

- SF3330.4S_102, 30 m3, 4 compartments, fifth-wheel 1250

- SF3330.4S_101, 30 m3, 4 compartments, fifth-wheel 1250

- SF3330.4S_100, 30 m3, 4 compartments, fifth-wheel 1250

- SF3330.3S_51, fifth-wheel 1250, 3 departments

- SF3330.3S_50, fifth-wheel 1250, 3 compartments

- SF3330.3N, fifth-wheel 1250, 3 compartments

- SF3330.4S_50, fifth-wheel 1250, 4 compartments

- SF3330.4S_51, fifth-wheel 1250, 4 compartments

- SF3330.3S_103, fifth-wheel 1250, 3 compartments

- SF3330

- SF3330.4S_08, fifth-wheel 1350, 4 compartments

- SF3330.3S_15, fifth-wheel 1450, 30 m3, 3 compartments

- SF3330.4S_07, fifth-wheel 1250, 4 compartments

- SF3330.3S_13, fifth-wheel 1350, 30 m3, 3 compartments

- SF3330.3S_11, fifth-wheel 1450, 30 m3, 3 compartments

- SF3330.3S_10, fifth-wheel 1350, 30 m3, 3 compartments

- SF3330.3S_09, fifth-wheel 1250, 30 m3, 3 compartments

- SF3330.3S_08, fifth-wheel 1500, 30 m3, 3 compartments

- SF3330.3S_06, fifth-wheel 1250, 30 m3, 3 compartments

- SF3330.3S_05, fifth-wheel 1250, 30 m3, 3 compartments

- SF3330.3S_16, fifth-wheel 1150, 3 compartments

- SF3330.5S_01, fifth-wheel 1250, 5 compartments

- SF3330.4S_03, fifth-wheel 1250, 4 compartments

- SF3330.5S_03, fifth-wheel 1250, 5 compartments

- SF3330.3S_04, fifth-wheel 1150, 30 m3, 3 compartments

- SF3328 AL

- SF3338 AL

- SF3325

- SF3340

- SF3340.4S_12, 40 m3, 4 compartments, fifth-wheel 1460

- SF3340.4S_11, 40 m3, 4 compartments, fifth-wheel 1460

- SF3340.4S_10, 40 m3, 4 compartments, fifth-wheel 1460

- SF3340.4S_09, 40 m3, 4 compartments, fifth-wheel 1460

- SF3340.4S_08, 40 m3, 4 compartments, fifth-wheel 1460

- SF3340.4S_07, 40 m3, 4 compartments, fifth-wheel 1450

- SF3340.4S_06, 40 m3, 4 compartments, fifth-wheel 1350

- SF3340.4S_05, 40 m3, 4 compartments, fifth-wheel 1250

- SF3340.4S_04, 40 m3, 4 compartments, fifth-wheel 1250

- SF3340.4S_03, 40 m3, 4 compartments, fifth-wheel 1450

- SF3340.4S_02, 40 m3, 4 compartments, fifth-wheel 1450

- SF3340.4S_01, 40 m3, 4 compartments, fifth-wheel 1250

- SF3345

- SF3332

- SF3332.4S, fifth-wheel 1250, 4 compartments_06

- SF3332.4S, fifth-wheel 1300, 4 compartments_07

- SF3332.4S, fifth-wheel 1300, 4 compartments_04

- SF3332.5S, fifth-wheel 1250, 5 compartments_01

- SF3332.4S, fifth-wheel 1300, 4 compartments_03

- SF3332.4S, fifth-wheel 1250, 4 compartments_02

- SF3332.4S, fifth-wheel 1250, 4 compartments_01

- SF3332.4A, fifth-wheel 1250, 4 compartments_01

- SF3330 AL

- Grain Trucks

- Dump Trucks

- Bulk Cement Trucks

- SF3U34

- SF3U32

- SF3U30

- SF3U30_1A fifth-wheel 1350, 1 compartment_100 cement

- SF3U30_1Afifth-wheel 1250, 1 compartment_02 cement

- SF3U30_1A fifth-wheel 1250, 1 compartment_01 cement

- 964817 fifth-wheel 1250, 2 compartments_04 cement

- 964817 fifth-wheel 1250, 2 compartments_03 cement

- 964817 fifth-wheel 1250, 2 compartments_02 cement

- 964817 fifth-wheel 1250, 2 compartment_01 cement

- SF2U14

- SF3U24

- SF2U25

- SF3U28

- SF3U27

- SF3U27_1A_15 fifth-wheel 1150, 1 compartment, 27 m3

- SF3U27_1A_14 fifth-wheel 1250, 1 compartment, 27 m3

- SF3U27_1A_13 fifth-wheel 1250, 1 compartment, 27 m3

- SF3U27_1A_12 fifth-wheel 1250, 1 compartment, 27 m3

- SF3U27_1A_11 fifth-wheel 1250, 1 compartment, 27 m3

- SF3U27_1A_10 fifth-wheel 1250, 1 compartment, 27 m3

- SF3U27_1A_09 fifth-wheel 1250, 1 compartment, 27 m3

- SF3U27_1A_08 fifth-wheel 1250, 1 compartment, 27 m3

- SF3U27_1A_07 fifth-wheel 1250, 1 compartment, 27 m3

- SF3U27_1A_05 fifth-wheel 1150, 1 compartment, 27 m3

- SF3U27_1A_01 fifth-wheel 1150, 1 compartment, 27 m3

- SF3U25

- Bitumen Tankers

- SF3B38

- SF3B38.1S_16, 38 m3, 1 compartment, fifth-wheel 1350

- SF3B38.1S_15, 38 m3, 1 compartment, fifth-wheel 1350

- SF3B38.1S_14, 38 m3, 1 compartment, fifth-wheel 1450

- SF3B38.1S_13, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_10, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_09, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_12, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_08, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_11, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_07, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_06, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_05, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_04, 38 m3, 1 compartment, fifth-wheel 1150

- SF3B38.1S_03, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_02, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_01, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B30 variable cross-section

- SF3B30.1S fifth-wheel 1500, 1 compartment_42

- SF3B30.1S fifth-wheel 1540, 1 compartment_40

- SF3B30.1S fifth-wheel 1450, 1 compartment_35

- SF3B30.1S fifth-wheel 1450, 1 compartment_34

- SF3B30.1S fifth-wheel 1450, 1 compartment_33

- SF3B30.1S fifth-wheel 1450, 1 compartment_32

- SF3B30.1S fifth-wheel 1450, 1 compartment_31

- SF3B30.1S fifth-wheel 1500, 1 compartment_24

- SF3B30.1S fifth-wheel 1450, 1 compartment_23

- SF3B30.1S fifth-wheel 1430, 1 compartment_05

- SF3B30.1S.14 fifth-wheel 1600, 1 compartment

- SF3B30.1S.15 fifth-wheel 1450, 1 compartment

- SF3B30.1S fifth-wheel 1450, 1 compartment_16

- SF3B30.1S fifth-wheel 1600, 1 compartment_19

- SF3B30.1S fifth-wheel 1450, 1 compartment_18

- SF3B30.1S fifth-wheel 1500, 1 compartment_20

- SF3B30

- SF3B30.1S fifth-wheel 1250, 1 compartment_41

- SF3B30.1S fifth-wheel 1250, 1 compartment_39

- SF3B30.1S fifth-wheel 1250, 1 compartment_37

- SF3B30.1S fifth-wheel 1150, 1 compartment_36

- SF3B30.1S fifth-wheel 1250, 1 compartment_30

- SF3B30.1S fifth-wheel 1150, 1 compartment_29

- SF3B30.1S fifth-wheel 1250, 1 compartment_27

- SF3B30.1S fifth-wheel 1250, 1 compartment_22

- SF3B30.1S fifth-wheel 1250, 1 compartment_21

- SF3B30.1S fifth-wheel 1350, 1 compartment_17

- SF3B30.1S fifth-wheel 1250, 1 compartment_13

- SF3B30.1S fifth-wheel 1250, 1 compartment_12

- SF3B30.1S fifth-wheel 1250, 1 compartment_11

- SF3B30.1S fifth-wheel 1250, 1 compartment_10

- SF3B30.1S fifth-wheel 1350, 1 compartment_09

- SF3B30.1S fifth-wheel 1250, 1 compartment_08

- SF3B30.1S fifth-wheel 1350, 1 compartment_07

- SF3B30.1S fifth-wheel 1350, 1 compartment_06

- SF3B30.1S fifth-wheel 1350, 1 compartment_03

- SF3B30.1S fifth-wheel 1350, 1 compartment_02

- SF3B30.1S fifth-wheel 1250, 1 compartment_01

- SF3B25

- SF3B25_1S_19, fifth-wheel 1150, 25 m3, 1 compartment

- SF3B25_1S_18, fifth-wheel 1350, 25 m3, 1 compartment

- SF3B25_1S_17, fifth-wheel 1350, 25 m3, 1 compartment

- SF3B25_1S_16, fifth-wheel 1250, 25 m3, 1 compartment

- SF3B25_1S_15, fifth-wheel 1250, 25 m3, 1 compartment

- SF3B25_1S_14, fifth-wheel 1150, 25 m3, 1 compartment

- SF3B25_1S_13, fifth-wheel 1250, 25 m3, 1 compartment

- SF3B25_1S_12, fifth-wheel 1250, 25 m3, 1 compartment

- SF3B25_1S_04, fifth-wheel 1350, 25 m3, 1 compartment

- SF3B25_1S_05, fifth-wheel 1350, 25 m3, 1 compartment

- SF3B25_1S_06, fifth-wheel 1250, 25 m3, 1 compartment

- SF3B25_1S_07, fifth-wheel 1250, 25 m3, 1 compartment

- SF3B25_1S_08, fifth-wheel 1250, 25 m3, 1 compartment

- SF3B25_1S_09, fifth-wheel 1350, 25 m3, 1 compartment

- SF3B25_1S_10, fifth-wheel 1250, 25 m3, 1 compartment

- SF3B30

- SF3B25

- SF3B28 variable cross-section

- SF3B28.1S_78, 28 m3, 1 compartment, fifth-wheel СУ 1450

- SF3B28.1S_74, 28 m3, 1 compartment, fifth-wheel СУ 1150

- SF3B28.1S_72, 28 m3, 1 compartment, fifth-wheel СУ 1350

- SF3B28.1S_71, 28 m3, 1 compartment, fifth-wheel СУ 1150

- SF3B28.1S_70, 28 m3, 1 compartment, fifth-wheel СУ 1150

- SF3B28.1S_59, 28 m3, 1 compartment, fifth-wheel СУ 1150

- SF3B28.1S_65, 28 m3, 1 compartment, fifth-wheel СУ 1150

- SF3B28.1S_57, 28 m3, 1 compartment, fifth-wheel СУ 1150

- SF3B28.1S_32, 28 m3, 1 compartment, fifth-wheel СУ 1150

- SF3B28.1S_41, 28 m3, 1 compartment, fifth-wheel СУ 1150

- SF3B28.1S_03, 28 m3, 1 compartment, fifth-wheel 1250

- SF3B28.1S_05, 28 m3, 1 compartment, fifth-wheel 1250

- SF3B23

- SF3B28

- SF3B28_1S_85, fifth-wheel 1150, 1 compartment

- SF3B28_1S_84, fifth-wheel 1150, 1 compartment

- SF3B28_1S_83, fifth-wheel 1150, 1 compartment

- SF3B28_1S_82, fifth-wheel 1150, 1 compartment

- SF3B28_1S_81, fifth-wheel 1150, 1 compartment

- SF3B28_1S_80, fifth-wheel 1150, 1 compartment

- SF3B28_1S_79, fifth-wheel 1250, 1 compartment

- SF3B28_1S_77, fifth-wheel 1250, 1 compartment

- SF3B28_1S_76, fifth-wheel 1250, 1 compartment

- SF3B28_1S_75, fifth-wheel 1250, 1 compartment

- SF3B28_1S_73, fifth-wheel 1150, 1 compartment

- SF3B28_1S_68, fifth-wheel 1150, 1 compartment

- SF3B28_1S_60, fifth-wheel 1150, 1 compartment

- SF3B28_1S_62, fifth-wheel 1250, 1 compartment

- SF3B28_1S_61, fifth-wheel 1250, 1 compartment

- SF3B28_1S_64, fifth-wheel 1250, 1 compartment

- SF3B28_1S_58, fifth-wheel 1350, 1 compartment

- SF3B28_1S_56, fifth-wheel 1250, 1 compartment

- SF3B28_1S_55, fifth-wheel 1150, 1 compartment

- SF3B28_1S_54, fifth-wheel 1250, 1 compartment

- SF3B28_1S_53, fifth-wheel 1150, 1 compartment

- SF3B28_1S_52, fifth-wheel 1250, 1 compartment

- SF3B28_1S_51, fifth-wheel 1250, 1 compartment

- SF3B28_1S_50, fifth-wheel 1250, 1 compartment

- SF3B28_2S_01, fifth-wheel 1250, 2 compartments

- SF3B28_1S_49, fifth-wheel 1250, 1 compartment

- SF3B28_1S_48, fifth-wheel 1250, 1 compartment

- SF3B28_1S_47, fifth-wheel 1150, 1 compartment

- SF3B28_1S_46, fifth-wheel 1250, 1 compartment

- SF3B28_1S_45, fifth-wheel 1250, 1 compartment

- SF3B28_1S_44, fifth-wheel 1250, 1 compartment

- SF3B28_1S_43, fifth-wheel 1250, 1 compartment

- SF3B28_1S_42, fifth-wheel 1250, 1 compartment

- SF3B28_1S_39, fifth-wheel 1150, 1 compartment

- SF3B28_1S_40, fifth-wheel 1150, 1 compartment

- SF3B28_1S_07, fifth-wheel 1250, 1 compartment

- SF3B28_1S_06, fifth-wheel 1250, 1 compartment

- SF3B28_1S_02, fifth-wheel 1150, 1 compartment

- SF3B28_1S_22, fifth-wheel 1250, 1 compartment

- SF3B28_1S_21, fifth-wheel 1250, 1 compartment

- SF3B28_1S_19, fifth-wheel 1250, 1 compartment

- SF3B28_1S_09, fifth-wheel 1250, 1 compartment

- SF3B38

- Flour Trucks

- SF3U31

- SF3U31.1S_11, 31 m3, fifth-wheel 1350

- SF3U31.1S_08, 31 m3, fifth-wheel 1150

- SF3U31.1S_07, 31 m3, fifth-wheel 1350

- SF3U31.1S_03, 31 m3, fifth-wheel 1350

- SF3U31.1S_04, 31 m3, fifth-wheel 1150

- SF3U31.1S_05, 31 m3, fifth-wheel 1300

- SF3U31.1S_06, 31 m3, fifth-wheel 1300

- SF3U31.1S_02, 31 m3, fifth-wheel 1150

- SF3U31.2S_01, 31 m3, fifth-wheel 1150

- SF3U31.1S_01, 31 m3, fifth-wheel 1300

- SF3U55

- SF3U55_4A_06, 55 m3, 4 compartments, fifth-wheel 1150

- SF3U55_4A_07, 55 m3, 4 compartments, fifth-wheel 1150

- SF3U55_4A_05, 55 m3, 4 compartments, fifth-wheel 1150

- SF3U55_4A_04, 55 m3, 4 compartments, fifth-wheel 1150

- SF3U55_4A_03, 55 m3, 4 compartments, fifth-wheel 1150

- SF3U55_4A_02, 55 m3, 4 compartments, fifth-wheel 1250

- SF3U55_3A_02, 55 m3, 3 compartments, fifth-wheel 1150

- SF3U55_3A_01 55 m3, 3 compartments, fifth-wheel 1150

- SF3U55_2A_02 55 m3, 2 compartments, fifth-wheel 1250

- SF3U55_2A_01 55 m3, 2 compartments, fifth-wheel 1250

- SF3U47

- SF3U48

- SF3U48_4A_04 fifth-wheel 1250, 4 compartments

- SF3U48_4A_03 fifth-wheel 1250, 4 compartments

- SF3U48_4A_02 fifth-wheel 1250, 4 compartments

- SF3U48_3A_28 fifth-wheel 1150, 3 compartments

- SF3U48_3A_27 fifth-wheel 1250, 3 compartments

- SF3U48_3A_26 fifth-wheel 1350, 3 compartments

- SF3U48_1A_18 fifth-wheel 1250, 1 compartment

- SF3U48_1A_17 fifth-wheel 1350, 1 compartment

- SF3U48_1A_16 fifth-wheel 1250, 1 compartment

- SF3U48_3A_23 fifth-wheel 1250, 3 compartments

- SF3U48_3A_22 fifth-wheel 1250, 3 compartments

- SF3U48_3A_20 fifth-wheel 1150, 3 compartments

- SF3U48_3A_19 fifth-wheel 1150, 3 compartments

- SF3U48_3A_18 fifth-wheel 1150, 3 compartments

- SF3U48_1A_13 fifth-wheel 1150, 1 compartment

- SF3U48_1A_11 fifth-wheel 1150, 1 compartment

- SF3U48_1A_10 fifth-wheel 1250, 1 compartment

- SF3U48_3A_16 fifth-wheel 1150, 3 compartments

- SF3U48_3A_24 fifth-wheel 1150, 3 compartments

- SF3U48_3A_25 fifth-wheel 1250, 3 compartments

- SF3U48_1A_08 fifth-wheel 1250, 1 compartment

- SF3U48_1A_09 fifth-wheel 1150, 1 compartment

- SF3U48_3A_13 fifth-wheel 1250, 3 compartments

- SF3U48_3A_12 fifth-wheel 1150, 3 compartments

- SF3U48_3A_17 fifth-wheel 1150, 3 compartments

- SF3U48_5A_02 fifth-wheel 1150, 5 compartments

- SF3U48_1A_12 fifth-wheel 1150, 3 compartment

- SF3U48_1A_14 fifth-wheel 1150, 1 compartment

- SF3U48_1A_15 fifth-wheel 1150, 1 compartment

- SF3U48_3A_01 fifth-wheel 1250, 3 compartments

- SF3U48_1A_07 fifth-wheel 1150, 1 compartment

- SF3U48_1A_06 fifth-wheel 1150, 1 compartment

- SF3U48_1A_04 fifth-wheel 1150, 1 compartment

- SF3U48_1A_03 fifth-wheel 1350, 1 compartment

- SF3U48_3A_10 fifth-wheel 1150, 3 compartments

- SF3U48_3A_09 fifth-wheel 1150, 3 compartments

- SF3U48_3A_08 fifth-wheel 1150, 3 compartments

- SF3U48_3A_07 fifth-wheel 1250, 3 compartments

- SF3U48_3A_06 fifth-wheel 1150, 3 compartments

- SF3U48_4A_01 fifth-wheel 1250, 4 compartments

- SF3U48_3A_11 fifth-wheel 1150, 3 compartments

- SF3U48_2A_03 fifth-wheel 1150, 2 compartments

- SF3U48_1A_05 fifth-wheel 1150, 3 compartments

- SF3U48_5A_01 fifth-wheel 1250, 5 compartments

- SF3U48_3A_05 fifth-wheel 1150, 3 compartments

- SF3U48_3A_04 fifth-wheel 1250, 3 compartments

- SF3U48_2A_02 fifth-wheel 1150, 2 compartments

- SF3U48_1A_02 fifth-wheel 1150, 1 compartment

- SF3U39

- SF3U39.5A_03 fifth-wheel 1250, 5 compartments

- SF3U39.5A_02 fifth-wheel 1150, 5 compartments

- SF3U39.3A_21, fifth-wheel 1150, 3 compartments

- SF3U39.3A_20, fifth-wheel 1150, 3 compartments

- SF3U39.3A_19, fifth-wheel 1150, 3 compartments

- SF3U39.3A_18, fifth-wheel 1150, 3 compartments

- SF3U39.2A_03, fifth-wheel 1150, 2 compartments

- SF3U39.1A_07, fifth-wheel 1250, 3 compartments

- SF3U39.1A_06, fifth-wheel 1150, 3 compartments

- SF3U39.1A_05, fifth-wheel 1150, 3 compartments

- SF3U39.3A_17, fifth-wheel 1150, 3 compartments

- SF3U39.3A_16, fifth-wheel 1150, 3 compartments

- SF3U39.5A_04 fifth-wheel 1150, 5 compartments

- SF3U39.2A_02, fifth-wheel 1150, 2 compartments

- SF3U39.3A_14, fifth-wheel 1150, 3 compartments

- SF3U39.1A_04, fifth-wheel 1150, 3 compartments

- SF3U39.1A_03, fifth-wheel 1150, 3 compartments

- SF3U39.3A_12, fifth-wheel 1150, 3 compartments

- SF3U39.3A_11, fifth-wheel 1250, 3 compartments

- SF3U39.3A_10, fifth-wheel 1150, 3 compartments

- SF3U39.3A_09, fifth-wheel 1150, 3 compartments

- SF3U39.2A_01, fifth-wheel 1150, 2 compartments

- SF3U39.3A_08, fifth-wheel 1150, 3 compartments

- SF3U39.3A_07, fifth-wheel 1150, 3 compartments

- SF3U39.3A_06, fifth-wheel 1250, 3 compartments

- SF3U39.3A_05, fifth-wheel 1250, 3 compartments

- SF3U39.3A_04, fifth-wheel 1150, 3 compartments

- SF3U39.3A_03, fifth-wheel 1350, 3 compartments

- SF3U39.3A_02, fifth-wheel 1350, 3 compartments

- SF3U39.5A fifth-wheel 1150, 5 compartments

- SF3U24

- SF3U25

- SF3U41

- SF3U41_3S_01 fifth-wheel 1150, 1 compartment

- SF3U41_5S_02 fifth-wheel 1250, 5 compartments

- SF3U41_3S_01 fifth-wheel 1150, 1 compartment

- SF3U41_5S_01 fifth-wheel 1350, 5 compartments

- SF3U41_4S_03 fifth-wheel 1200, 4 compartments

- SF3U41_1S_01 fifth-wheel 1200, 1 compartment

- SF3U41_1S_02 fifth-wheel 1250, 1 compartment

- SF2U32

- SF3U31

- LPG Tankers

- Food Products Tankers

- 3-axle semitrailer for food products transportation SB3025

- SB4032

- SF4032

- 3-axle semitrailer for food products transportation SF3025

- 3-axle semitrailer for food products transportation SF3E30

- Semitrailer for food liquids transportation SF3E30_3N_01

- Semitrailer for food liquids transportation SF3E30_1N_06

- Semitrailer for food liquids transportation SF3E30_1N_05

- Semitrailer for food liquids transportation SF3E30_1N_04

- Semitrailer for food liquids transportation SF3E30_1N_03

- Semitrailer for food liquids transportation SF3E30_1N_02

- Semitrailer for food liquids transportation SF3E30_1N

- 3-axle semitrailer for food products transportation SF3030

- Semitrailer for food liquids transportation SF3030_3N_01

- Semitrailer for food liquids transportation SF3030_1N_05

- Semitrailer for food liquids transportation SF3030_4N_02

- Semitrailer for food liquids transportation SF3030_4N_01

- Semitrailer for food liquids transportation SF3030_2N_01

- Semitrailer for food liquids transportation SF3030_1N_04

- Semitrailer for food liquids transportation SF3030_1N_03

- Semitrailer for food liquids transportation SF3030_1N_02

- SF4032

- SF4032.3N_04, 32 m3, 3 compartments, fifth-wheel 1250

- SF4032.1N_04, 32 m3, 3 compartments, fifth-wheel 1150

- SF4032.4N_02, 32 m3, 4 compartments, fifth-wheel 1250

- SF4032.1N_02, 32 m3, 3 compartments, fifth-wheel 1250

- SF4032.1N_01, 32 m3, 3 compartments, fifth-wheel 1250

- SF4032.1N_03, 32 m3, 3 compartments, fifth-wheel 1250

- SF4032.4N_01, 32 m3, 4 compartments, fifth-wheel 1250

- SF4032.3N_01, 32 m3, 3 compartments, fifth-wheel 1250

- Chemical Tankers

- SF4242

- Tankers for chemicals transportation SF3830

- Chemical Tanker SF3930

- SF4930

- Chemical Tanker SF3928

- Tanker SF3918_1N_02, 18 m3, 1 compartments, fifth-wheel 1250

- Tanker SF3918_1N_01, 18 m3, 1 compartments, fifth-wheel 1350

- Tanker SF3918_1S_01, 18 m3, 1 compartments, fifth-wheel 1450

- Tanker SF3918_2S_01, 18 m3, 2 compartments, fifth-wheel 1250

- Tanker SF3918_2N_01, 18 m3, 2 compartments, fifth-wheel 1250

- SF4932

- SF4932.3S_01, 32m3, 3 compartments, fifth-wheel 1150

- SF4932.5N_01, 32 m3, 5 compartments, fifth-wheel 1150

- SF4932.4N_02, 32 m3, 4 compartments, fifth-wheel 1250

- SF4932.4N_01, 32 m3, 4 compartments, fifth-wheel 1250

- SF4932.3N_02, 32m3, 3 compartments, fifth-wheel 1250

- SF4932.3N_01, 32m3, 1 compartments, fifth-wheel 1250

- Chemical Tanker SF3928

- Tanker SF3928.4N_02, 28 m3, 1 compartments, fifth-wheel 1250

- Tanker SF3928.3N_04, 28 m3, 1 compartments, fifth-wheel 1250

- Tanker SF3928.4N_03, 28 m3, 4 compartments, fifth-wheel 1150

- Tanker SF3928.4N_01, 28 m3, 1 compartments, fifth-wheel 1250

- Tanker SF3928.3N_03, 28 m3, 1 compartments, fifth-wheel 1250

- Tanker SF3928.3N_02, 28 m3, 1 compartments, fifth-wheel 1250

- Tanker SF3928.3N_01, 28 m3, 1 compartments, fifth-wheel 1250

- Chemical Tankers 96487t, 28 m3, 1 compartment, fifth-wheel 1150

- Chemical Tanker SF3920

- Tankers for chemicals transportation SF3825

- Trailers

- Tank-Containers

- Tipping Silos

- 4-axle semitrailers

- Tank Trucks

- Cesspool emptying machine

- Cryogenic tankers

- Cryogenic tank containers

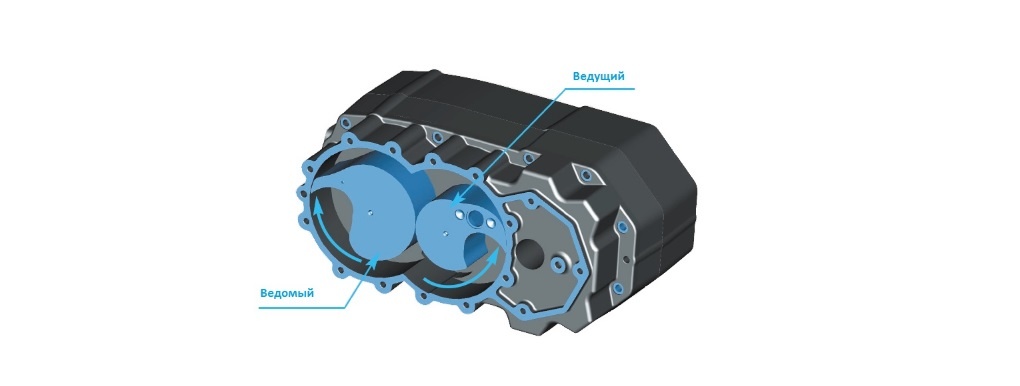

Compressor unit КС-400

Compressor КС-400 is designed to compress and supply air under pressure. The main characteristic of this compressor is that it does not add oil to the compressed air, which is very important for the food industry, where air purity is important. The compressor is used on semitrailers intended for: flour, cereals, animal feed, lime, lime materials, sand, plastic granules, gravel, cement, etc.

The compressor is designed as an easy to maintain, reliable in operation and inexpensive unit. The direct drive from the cardan shaft saves additional costs for V-belt or chain drives and the resulting consequential costs. The pulsating supply of compressed air helps during unloading of the product, preventing the formation of "plugs".

Operating conditions

The compressor is manufactured according to the technical documentation of SESPEL Cheboksary enterprise, CJSC in the climatic version "Y1" in accordance with GOST 15150 and is operated at:

- ambient air temperature from minus 40 to plus 50 degrees Celsius;

- relative air humidity, up to 80% at 20 оС.

Technical characteristics

| Basic parameters | Values |

| Feed (delivery volume), m3/h | 260...480 |

| Initial pressure | atmospheric |

| Working pressure, MPa (kp/cm2) | 0,15(1,5) |

| Maximum pressure, MPa (kp/cm2) | 0,20 (2,0) |

|

Consumed power at working pressure, kW, no more than |

27,5 |

| Consumed power at maximum pressure, kW, no more than | 32,5 |

| Rotational speed, rpm | 1 400 |

| Compressor cooling | air |

| Length, mm |

254,4 |

| Width, mm |

432 |

| Height, mm |

531 |

| Weight (without lubrication), kg, no more than |

115 |

Compressor structure and functioning

The compressor is a mechanism with a positive value of the working chamber volume. During compressor operation the atmospheric air through the air filter enters the cam block, in which the air is compressed by rotating cams. The air enters the compression space which is formed by two cams and the cam block body. When the cam block rotates, the space "moves" and decreases in volume. Thus, the air is compressed. The rotation of the cams is provided by the drive and the drive clutch.