- Fuel Tankers

- SF3330 AL

- SF3330_3A_10, 30 m3, 3 compartments, fifth-wheel 1150

- SF3330_5A_13, 30 m3, 5 compartments, fifth-wheel 1150

- SF3330_5A_04, 30 m3, 5 compartments, fifth-wheel 1150

- SF3330_5A_03, 30 m3, 5 compartments, fifth-wheel 1250

- SF3330_3A_08, 30 m3, 3 compartments, fifth-wheel 1250

- SF3330_5A_14, 30 m3, 5 compartments, fifth-wheel 1250

- SF3330_3A_07, 30 m3, 3 compartments, fifth-wheel 1250

- SF3330_3A_05, 30 m3, 3 compartments, fifth-wheel 1250

- SF3330_3A_04, 30 m3, 3 compartments, fifth-wheel 1250

- SF3330_3A_03, 30 m3, 3 compartments, fifth-wheel 1250

- SF3330_3A_02, 30 m3, 3 compartments, fifth-wheel 1250

- SF3330_3A_01, 30 m3, 3 compartments, fifth-wheel 1250

- SF3330_3A_06, 30 m3, 3 compartments, fifth-wheel 1250

- SF3330_4A_02, 30 m3, 4 compartments, fifth-wheel 1250

- SF3330_4A_03, 30 m3, 4 compartments, fifth-wheel 1200

- SF3330_4A_11, 30 m3, 4 compartments, fifth-wheel 1250

- SF3330_5A_11, 30 m3, 5 compartments, fifth-wheel 1250

- SF3330_5A_12, 30 m3, 5 compartments, fifth-wheel 1250

- SF3330 BG

- SF3330.4S_110, fifth-wheel 1250, 4 compartments

- SF3330.4S_113, fifth-wheel 1250, 4 compartments

- SF3330.3S_109, fifth-wheel 1250, 3 compartments

- SF3330.3A_101, fifth-wheel 1250, 3 compartments

- SF3330.4S_108, 30 m3, 4 compartments, fifth-wheel 1250

- SF3330.4S_103, 29 m3, 4 compartments, fifth-wheel 1250

- SF3330.4S_102, 30 m3, 4 compartments, fifth-wheel 1250

- SF3330.4S_101, 30 m3, 4 compartments, fifth-wheel 1250

- SF3330.4S_100, 30 m3, 4 compartments, fifth-wheel 1250

- SF3330.3S_51, fifth-wheel 1250, 3 departments

- SF3330.3S_50, fifth-wheel 1250, 3 compartments

- SF3330.3N, fifth-wheel 1250, 3 compartments

- SF3330.4S_50, fifth-wheel 1250, 4 compartments

- SF3330.4S_51, fifth-wheel 1250, 4 compartments

- SF3330.3S_103, fifth-wheel 1250, 3 compartments

- SF3330

- SF3330.4S_08, fifth-wheel 1350, 4 compartments

- SF3330.3S_15, fifth-wheel 1450, 30 m3, 3 compartments

- SF3330.4S_07, fifth-wheel 1250, 4 compartments

- SF3330.3S_13, fifth-wheel 1350, 30 m3, 3 compartments

- SF3330.3S_11, fifth-wheel 1450, 30 m3, 3 compartments

- SF3330.3S_10, fifth-wheel 1350, 30 m3, 3 compartments

- SF3330.3S_09, fifth-wheel 1250, 30 m3, 3 compartments

- SF3330.3S_08, fifth-wheel 1500, 30 m3, 3 compartments

- SF3330.3S_06, fifth-wheel 1250, 30 m3, 3 compartments

- SF3330.3S_05, fifth-wheel 1250, 30 m3, 3 compartments

- SF3330.3S_16, fifth-wheel 1150, 3 compartments

- SF3330.5S_01, fifth-wheel 1250, 5 compartments

- SF3330.4S_03, fifth-wheel 1250, 4 compartments

- SF3330.5S_03, fifth-wheel 1250, 5 compartments

- SF3330.3S_04, fifth-wheel 1150, 30 m3, 3 compartments

- SF3328 AL

- SF3338 AL

- SF3325

- SF3340

- SF3340.4S_12, 40 m3, 4 compartments, fifth-wheel 1460

- SF3340.4S_11, 40 m3, 4 compartments, fifth-wheel 1460

- SF3340.4S_10, 40 m3, 4 compartments, fifth-wheel 1460

- SF3340.4S_09, 40 m3, 4 compartments, fifth-wheel 1460

- SF3340.4S_08, 40 m3, 4 compartments, fifth-wheel 1460

- SF3340.4S_07, 40 m3, 4 compartments, fifth-wheel 1450

- SF3340.4S_06, 40 m3, 4 compartments, fifth-wheel 1350

- SF3340.4S_05, 40 m3, 4 compartments, fifth-wheel 1250

- SF3340.4S_04, 40 m3, 4 compartments, fifth-wheel 1250

- SF3340.4S_03, 40 m3, 4 compartments, fifth-wheel 1450

- SF3340.4S_02, 40 m3, 4 compartments, fifth-wheel 1450

- SF3340.4S_01, 40 m3, 4 compartments, fifth-wheel 1250

- SF3345

- SF3332

- SF3332.4S, fifth-wheel 1250, 4 compartments_06

- SF3332.4S, fifth-wheel 1300, 4 compartments_07

- SF3332.4S, fifth-wheel 1300, 4 compartments_04

- SF3332.5S, fifth-wheel 1250, 5 compartments_01

- SF3332.4S, fifth-wheel 1300, 4 compartments_03

- SF3332.4S, fifth-wheel 1250, 4 compartments_02

- SF3332.4S, fifth-wheel 1250, 4 compartments_01

- SF3332.4A, fifth-wheel 1250, 4 compartments_01

- SF3330 AL

- Grain Trucks

- Dump Trucks

- Bulk Cement Trucks

- SF3U34

- SF3U32

- SF3U30

- SF3U30_1A fifth-wheel 1350, 1 compartment_100 cement

- SF3U30_1Afifth-wheel 1250, 1 compartment_02 cement

- SF3U30_1A fifth-wheel 1250, 1 compartment_01 cement

- 964817 fifth-wheel 1250, 2 compartments_04 cement

- 964817 fifth-wheel 1250, 2 compartments_03 cement

- 964817 fifth-wheel 1250, 2 compartments_02 cement

- 964817 fifth-wheel 1250, 2 compartment_01 cement

- SF2U14

- SF3U24

- SF2U25

- SF3U28

- SF3U27

- SF3U27_1A_15 fifth-wheel 1150, 1 compartment, 27 m3

- SF3U27_1A_14 fifth-wheel 1250, 1 compartment, 27 m3

- SF3U27_1A_13 fifth-wheel 1250, 1 compartment, 27 m3

- SF3U27_1A_12 fifth-wheel 1250, 1 compartment, 27 m3

- SF3U27_1A_11 fifth-wheel 1250, 1 compartment, 27 m3

- SF3U27_1A_10 fifth-wheel 1250, 1 compartment, 27 m3

- SF3U27_1A_09 fifth-wheel 1250, 1 compartment, 27 m3

- SF3U27_1A_08 fifth-wheel 1250, 1 compartment, 27 m3

- SF3U27_1A_07 fifth-wheel 1250, 1 compartment, 27 m3

- SF3U27_1A_05 fifth-wheel 1150, 1 compartment, 27 m3

- SF3U27_1A_01 fifth-wheel 1150, 1 compartment, 27 m3

- SF3U25

- Bitumen Tankers

- SF3B38

- SF3B38.1S_16, 38 m3, 1 compartment, fifth-wheel 1350

- SF3B38.1S_15, 38 m3, 1 compartment, fifth-wheel 1350

- SF3B38.1S_14, 38 m3, 1 compartment, fifth-wheel 1450

- SF3B38.1S_13, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_10, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_09, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_12, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_08, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_11, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_07, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_06, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_05, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_04, 38 m3, 1 compartment, fifth-wheel 1150

- SF3B38.1S_03, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_02, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B38.1S_01, 38 m3, 1 compartment, fifth-wheel 1250

- SF3B30 variable cross-section

- SF3B30.1S fifth-wheel 1500, 1 compartment_42

- SF3B30.1S fifth-wheel 1540, 1 compartment_40

- SF3B30.1S fifth-wheel 1450, 1 compartment_35

- SF3B30.1S fifth-wheel 1450, 1 compartment_34

- SF3B30.1S fifth-wheel 1450, 1 compartment_33

- SF3B30.1S fifth-wheel 1450, 1 compartment_32

- SF3B30.1S fifth-wheel 1450, 1 compartment_31

- SF3B30.1S fifth-wheel 1500, 1 compartment_24

- SF3B30.1S fifth-wheel 1450, 1 compartment_23

- SF3B30.1S fifth-wheel 1430, 1 compartment_05

- SF3B30.1S.14 fifth-wheel 1600, 1 compartment

- SF3B30.1S.15 fifth-wheel 1450, 1 compartment

- SF3B30.1S fifth-wheel 1450, 1 compartment_16

- SF3B30.1S fifth-wheel 1600, 1 compartment_19

- SF3B30.1S fifth-wheel 1450, 1 compartment_18

- SF3B30.1S fifth-wheel 1500, 1 compartment_20

- SF3B30

- SF3B30.1S fifth-wheel 1250, 1 compartment_41

- SF3B30.1S fifth-wheel 1250, 1 compartment_39

- SF3B30.1S fifth-wheel 1250, 1 compartment_37

- SF3B30.1S fifth-wheel 1150, 1 compartment_36

- SF3B30.1S fifth-wheel 1250, 1 compartment_30

- SF3B30.1S fifth-wheel 1150, 1 compartment_29

- SF3B30.1S fifth-wheel 1250, 1 compartment_27

- SF3B30.1S fifth-wheel 1250, 1 compartment_22

- SF3B30.1S fifth-wheel 1250, 1 compartment_21

- SF3B30.1S fifth-wheel 1350, 1 compartment_17

- SF3B30.1S fifth-wheel 1250, 1 compartment_13

- SF3B30.1S fifth-wheel 1250, 1 compartment_12

- SF3B30.1S fifth-wheel 1250, 1 compartment_11

- SF3B30.1S fifth-wheel 1250, 1 compartment_10

- SF3B30.1S fifth-wheel 1350, 1 compartment_09

- SF3B30.1S fifth-wheel 1250, 1 compartment_08

- SF3B30.1S fifth-wheel 1350, 1 compartment_07

- SF3B30.1S fifth-wheel 1350, 1 compartment_06

- SF3B30.1S fifth-wheel 1350, 1 compartment_03

- SF3B30.1S fifth-wheel 1350, 1 compartment_02

- SF3B30.1S fifth-wheel 1250, 1 compartment_01

- SF3B25

- SF3B25_1S_19, fifth-wheel 1150, 25 m3, 1 compartment

- SF3B25_1S_18, fifth-wheel 1350, 25 m3, 1 compartment

- SF3B25_1S_17, fifth-wheel 1350, 25 m3, 1 compartment

- SF3B25_1S_16, fifth-wheel 1250, 25 m3, 1 compartment

- SF3B25_1S_15, fifth-wheel 1250, 25 m3, 1 compartment

- SF3B25_1S_14, fifth-wheel 1150, 25 m3, 1 compartment

- SF3B25_1S_13, fifth-wheel 1250, 25 m3, 1 compartment

- SF3B25_1S_12, fifth-wheel 1250, 25 m3, 1 compartment

- SF3B25_1S_04, fifth-wheel 1350, 25 m3, 1 compartment

- SF3B25_1S_05, fifth-wheel 1350, 25 m3, 1 compartment

- SF3B25_1S_06, fifth-wheel 1250, 25 m3, 1 compartment

- SF3B25_1S_07, fifth-wheel 1250, 25 m3, 1 compartment

- SF3B25_1S_08, fifth-wheel 1250, 25 m3, 1 compartment

- SF3B25_1S_09, fifth-wheel 1350, 25 m3, 1 compartment

- SF3B25_1S_10, fifth-wheel 1250, 25 m3, 1 compartment

- SF3B30

- SF3B25

- SF3B28 variable cross-section

- SF3B28.1S_78, 28 m3, 1 compartment, fifth-wheel СУ 1450

- SF3B28.1S_74, 28 m3, 1 compartment, fifth-wheel СУ 1150

- SF3B28.1S_72, 28 m3, 1 compartment, fifth-wheel СУ 1350

- SF3B28.1S_71, 28 m3, 1 compartment, fifth-wheel СУ 1150

- SF3B28.1S_70, 28 m3, 1 compartment, fifth-wheel СУ 1150

- SF3B28.1S_59, 28 m3, 1 compartment, fifth-wheel СУ 1150

- SF3B28.1S_65, 28 m3, 1 compartment, fifth-wheel СУ 1150

- SF3B28.1S_57, 28 m3, 1 compartment, fifth-wheel СУ 1150

- SF3B28.1S_32, 28 m3, 1 compartment, fifth-wheel СУ 1150

- SF3B28.1S_41, 28 m3, 1 compartment, fifth-wheel СУ 1150

- SF3B28.1S_03, 28 m3, 1 compartment, fifth-wheel 1250

- SF3B28.1S_05, 28 m3, 1 compartment, fifth-wheel 1250

- SF3B23

- SF3B28

- SF3B28_1S_85, fifth-wheel 1150, 1 compartment

- SF3B28_1S_84, fifth-wheel 1150, 1 compartment

- SF3B28_1S_83, fifth-wheel 1150, 1 compartment

- SF3B28_1S_82, fifth-wheel 1150, 1 compartment

- SF3B28_1S_81, fifth-wheel 1150, 1 compartment

- SF3B28_1S_80, fifth-wheel 1150, 1 compartment

- SF3B28_1S_79, fifth-wheel 1250, 1 compartment

- SF3B28_1S_77, fifth-wheel 1250, 1 compartment

- SF3B28_1S_76, fifth-wheel 1250, 1 compartment

- SF3B28_1S_75, fifth-wheel 1250, 1 compartment

- SF3B28_1S_73, fifth-wheel 1150, 1 compartment

- SF3B28_1S_68, fifth-wheel 1150, 1 compartment

- SF3B28_1S_60, fifth-wheel 1150, 1 compartment

- SF3B28_1S_62, fifth-wheel 1250, 1 compartment

- SF3B28_1S_61, fifth-wheel 1250, 1 compartment

- SF3B28_1S_64, fifth-wheel 1250, 1 compartment

- SF3B28_1S_58, fifth-wheel 1350, 1 compartment

- SF3B28_1S_56, fifth-wheel 1250, 1 compartment

- SF3B28_1S_55, fifth-wheel 1150, 1 compartment

- SF3B28_1S_54, fifth-wheel 1250, 1 compartment

- SF3B28_1S_53, fifth-wheel 1150, 1 compartment

- SF3B28_1S_52, fifth-wheel 1250, 1 compartment

- SF3B28_1S_51, fifth-wheel 1250, 1 compartment

- SF3B28_1S_50, fifth-wheel 1250, 1 compartment

- SF3B28_2S_01, fifth-wheel 1250, 2 compartments

- SF3B28_1S_49, fifth-wheel 1250, 1 compartment

- SF3B28_1S_48, fifth-wheel 1250, 1 compartment

- SF3B28_1S_47, fifth-wheel 1150, 1 compartment

- SF3B28_1S_46, fifth-wheel 1250, 1 compartment

- SF3B28_1S_45, fifth-wheel 1250, 1 compartment

- SF3B28_1S_44, fifth-wheel 1250, 1 compartment

- SF3B28_1S_43, fifth-wheel 1250, 1 compartment

- SF3B28_1S_42, fifth-wheel 1250, 1 compartment

- SF3B28_1S_39, fifth-wheel 1150, 1 compartment

- SF3B28_1S_40, fifth-wheel 1150, 1 compartment

- SF3B28_1S_07, fifth-wheel 1250, 1 compartment

- SF3B28_1S_06, fifth-wheel 1250, 1 compartment

- SF3B28_1S_02, fifth-wheel 1150, 1 compartment

- SF3B28_1S_22, fifth-wheel 1250, 1 compartment

- SF3B28_1S_21, fifth-wheel 1250, 1 compartment

- SF3B28_1S_19, fifth-wheel 1250, 1 compartment

- SF3B28_1S_09, fifth-wheel 1250, 1 compartment

- SF3B38

- Flour Trucks

- SF3U31

- SF3U31.1S_11, 31 m3, fifth-wheel 1350

- SF3U31.1S_08, 31 m3, fifth-wheel 1150

- SF3U31.1S_07, 31 m3, fifth-wheel 1350

- SF3U31.1S_03, 31 m3, fifth-wheel 1350

- SF3U31.1S_04, 31 m3, fifth-wheel 1150

- SF3U31.1S_05, 31 m3, fifth-wheel 1300

- SF3U31.1S_06, 31 m3, fifth-wheel 1300

- SF3U31.1S_02, 31 m3, fifth-wheel 1150

- SF3U31.2S_01, 31 m3, fifth-wheel 1150

- SF3U31.1S_01, 31 m3, fifth-wheel 1300

- SF3U55

- SF3U55_4A_06, 55 m3, 4 compartments, fifth-wheel 1150

- SF3U55_4A_07, 55 m3, 4 compartments, fifth-wheel 1150

- SF3U55_4A_05, 55 m3, 4 compartments, fifth-wheel 1150

- SF3U55_4A_04, 55 m3, 4 compartments, fifth-wheel 1150

- SF3U55_4A_03, 55 m3, 4 compartments, fifth-wheel 1150

- SF3U55_4A_02, 55 m3, 4 compartments, fifth-wheel 1250

- SF3U55_3A_02, 55 m3, 3 compartments, fifth-wheel 1150

- SF3U55_3A_01 55 m3, 3 compartments, fifth-wheel 1150

- SF3U55_2A_02 55 m3, 2 compartments, fifth-wheel 1250

- SF3U55_2A_01 55 m3, 2 compartments, fifth-wheel 1250

- SF3U47

- SF3U48

- SF3U48_4A_04 fifth-wheel 1250, 4 compartments

- SF3U48_4A_03 fifth-wheel 1250, 4 compartments

- SF3U48_4A_02 fifth-wheel 1250, 4 compartments

- SF3U48_3A_28 fifth-wheel 1150, 3 compartments

- SF3U48_3A_27 fifth-wheel 1250, 3 compartments

- SF3U48_3A_26 fifth-wheel 1350, 3 compartments

- SF3U48_1A_18 fifth-wheel 1250, 1 compartment

- SF3U48_1A_17 fifth-wheel 1350, 1 compartment

- SF3U48_1A_16 fifth-wheel 1250, 1 compartment

- SF3U48_3A_23 fifth-wheel 1250, 3 compartments

- SF3U48_3A_22 fifth-wheel 1250, 3 compartments

- SF3U48_3A_20 fifth-wheel 1150, 3 compartments

- SF3U48_3A_19 fifth-wheel 1150, 3 compartments

- SF3U48_3A_18 fifth-wheel 1150, 3 compartments

- SF3U48_1A_13 fifth-wheel 1150, 1 compartment

- SF3U48_1A_11 fifth-wheel 1150, 1 compartment

- SF3U48_1A_10 fifth-wheel 1250, 1 compartment

- SF3U48_3A_16 fifth-wheel 1150, 3 compartments

- SF3U48_3A_24 fifth-wheel 1150, 3 compartments

- SF3U48_3A_25 fifth-wheel 1250, 3 compartments

- SF3U48_1A_08 fifth-wheel 1250, 1 compartment

- SF3U48_1A_09 fifth-wheel 1150, 1 compartment

- SF3U48_3A_13 fifth-wheel 1250, 3 compartments

- SF3U48_3A_12 fifth-wheel 1150, 3 compartments

- SF3U48_3A_17 fifth-wheel 1150, 3 compartments

- SF3U48_5A_02 fifth-wheel 1150, 5 compartments

- SF3U48_1A_12 fifth-wheel 1150, 3 compartment

- SF3U48_1A_14 fifth-wheel 1150, 1 compartment

- SF3U48_1A_15 fifth-wheel 1150, 1 compartment

- SF3U48_3A_01 fifth-wheel 1250, 3 compartments

- SF3U48_1A_07 fifth-wheel 1150, 1 compartment

- SF3U48_1A_06 fifth-wheel 1150, 1 compartment

- SF3U48_1A_04 fifth-wheel 1150, 1 compartment

- SF3U48_1A_03 fifth-wheel 1350, 1 compartment

- SF3U48_3A_10 fifth-wheel 1150, 3 compartments

- SF3U48_3A_09 fifth-wheel 1150, 3 compartments

- SF3U48_3A_08 fifth-wheel 1150, 3 compartments

- SF3U48_3A_07 fifth-wheel 1250, 3 compartments

- SF3U48_3A_06 fifth-wheel 1150, 3 compartments

- SF3U48_4A_01 fifth-wheel 1250, 4 compartments

- SF3U48_3A_11 fifth-wheel 1150, 3 compartments

- SF3U48_2A_03 fifth-wheel 1150, 2 compartments

- SF3U48_1A_05 fifth-wheel 1150, 3 compartments

- SF3U48_5A_01 fifth-wheel 1250, 5 compartments

- SF3U48_3A_05 fifth-wheel 1150, 3 compartments

- SF3U48_3A_04 fifth-wheel 1250, 3 compartments

- SF3U48_2A_02 fifth-wheel 1150, 2 compartments

- SF3U48_1A_02 fifth-wheel 1150, 1 compartment

- SF3U39

- SF3U39.5A_03 fifth-wheel 1250, 5 compartments

- SF3U39.5A_02 fifth-wheel 1150, 5 compartments

- SF3U39.3A_21, fifth-wheel 1150, 3 compartments

- SF3U39.3A_20, fifth-wheel 1150, 3 compartments

- SF3U39.3A_19, fifth-wheel 1150, 3 compartments

- SF3U39.3A_18, fifth-wheel 1150, 3 compartments

- SF3U39.2A_03, fifth-wheel 1150, 2 compartments

- SF3U39.1A_07, fifth-wheel 1250, 3 compartments

- SF3U39.1A_06, fifth-wheel 1150, 3 compartments

- SF3U39.1A_05, fifth-wheel 1150, 3 compartments

- SF3U39.3A_17, fifth-wheel 1150, 3 compartments

- SF3U39.3A_16, fifth-wheel 1150, 3 compartments

- SF3U39.5A_04 fifth-wheel 1150, 5 compartments

- SF3U39.2A_02, fifth-wheel 1150, 2 compartments

- SF3U39.3A_14, fifth-wheel 1150, 3 compartments

- SF3U39.1A_04, fifth-wheel 1150, 3 compartments

- SF3U39.1A_03, fifth-wheel 1150, 3 compartments

- SF3U39.3A_12, fifth-wheel 1150, 3 compartments

- SF3U39.3A_11, fifth-wheel 1250, 3 compartments

- SF3U39.3A_10, fifth-wheel 1150, 3 compartments

- SF3U39.3A_09, fifth-wheel 1150, 3 compartments

- SF3U39.2A_01, fifth-wheel 1150, 2 compartments

- SF3U39.3A_08, fifth-wheel 1150, 3 compartments

- SF3U39.3A_07, fifth-wheel 1150, 3 compartments

- SF3U39.3A_06, fifth-wheel 1250, 3 compartments

- SF3U39.3A_05, fifth-wheel 1250, 3 compartments

- SF3U39.3A_04, fifth-wheel 1150, 3 compartments

- SF3U39.3A_03, fifth-wheel 1350, 3 compartments

- SF3U39.3A_02, fifth-wheel 1350, 3 compartments

- SF3U39.5A fifth-wheel 1150, 5 compartments

- SF3U24

- SF3U25

- SF3U41

- SF3U41_3S_01 fifth-wheel 1150, 1 compartment

- SF3U41_5S_02 fifth-wheel 1250, 5 compartments

- SF3U41_3S_01 fifth-wheel 1150, 1 compartment

- SF3U41_5S_01 fifth-wheel 1350, 5 compartments

- SF3U41_4S_03 fifth-wheel 1200, 4 compartments

- SF3U41_1S_01 fifth-wheel 1200, 1 compartment

- SF3U41_1S_02 fifth-wheel 1250, 1 compartment

- SF2U32

- SF3U31

- LPG Tankers

- Food Products Tankers

- 3-axle semitrailer for food products transportation SB3025

- SB4032

- SF4032

- 3-axle semitrailer for food products transportation SF3025

- 3-axle semitrailer for food products transportation SF3E30

- Semitrailer for food liquids transportation SF3E30_3N_01

- Semitrailer for food liquids transportation SF3E30_1N_06

- Semitrailer for food liquids transportation SF3E30_1N_05

- Semitrailer for food liquids transportation SF3E30_1N_04

- Semitrailer for food liquids transportation SF3E30_1N_03

- Semitrailer for food liquids transportation SF3E30_1N_02

- Semitrailer for food liquids transportation SF3E30_1N

- 3-axle semitrailer for food products transportation SF3030

- Semitrailer for food liquids transportation SF3030_3N_01

- Semitrailer for food liquids transportation SF3030_1N_05

- Semitrailer for food liquids transportation SF3030_4N_02

- Semitrailer for food liquids transportation SF3030_4N_01

- Semitrailer for food liquids transportation SF3030_2N_01

- Semitrailer for food liquids transportation SF3030_1N_04

- Semitrailer for food liquids transportation SF3030_1N_03

- Semitrailer for food liquids transportation SF3030_1N_02

- SF4032

- SF4032.3N_04, 32 m3, 3 compartments, fifth-wheel 1250

- SF4032.1N_04, 32 m3, 3 compartments, fifth-wheel 1150

- SF4032.4N_02, 32 m3, 4 compartments, fifth-wheel 1250

- SF4032.1N_02, 32 m3, 3 compartments, fifth-wheel 1250

- SF4032.1N_01, 32 m3, 3 compartments, fifth-wheel 1250

- SF4032.1N_03, 32 m3, 3 compartments, fifth-wheel 1250

- SF4032.4N_01, 32 m3, 4 compartments, fifth-wheel 1250

- SF4032.3N_01, 32 m3, 3 compartments, fifth-wheel 1250

- Chemical Tankers

- SF4242

- Tankers for chemicals transportation SF3830

- Chemical Tanker SF3930

- SF4930

- Chemical Tanker SF3928

- Tanker SF3918_1N_02, 18 m3, 1 compartments, fifth-wheel 1250

- Tanker SF3918_1N_01, 18 m3, 1 compartments, fifth-wheel 1350

- Tanker SF3918_1S_01, 18 m3, 1 compartments, fifth-wheel 1450

- Tanker SF3918_2S_01, 18 m3, 2 compartments, fifth-wheel 1250

- Tanker SF3918_2N_01, 18 m3, 2 compartments, fifth-wheel 1250

- SF4932

- SF4932.3S_01, 32m3, 3 compartments, fifth-wheel 1150

- SF4932.5N_01, 32 m3, 5 compartments, fifth-wheel 1150

- SF4932.4N_02, 32 m3, 4 compartments, fifth-wheel 1250

- SF4932.4N_01, 32 m3, 4 compartments, fifth-wheel 1250

- SF4932.3N_02, 32m3, 3 compartments, fifth-wheel 1250

- SF4932.3N_01, 32m3, 1 compartments, fifth-wheel 1250

- Chemical Tanker SF3928

- Tanker SF3928.4N_02, 28 m3, 1 compartments, fifth-wheel 1250

- Tanker SF3928.3N_04, 28 m3, 1 compartments, fifth-wheel 1250

- Tanker SF3928.4N_03, 28 m3, 4 compartments, fifth-wheel 1150

- Tanker SF3928.4N_01, 28 m3, 1 compartments, fifth-wheel 1250

- Tanker SF3928.3N_03, 28 m3, 1 compartments, fifth-wheel 1250

- Tanker SF3928.3N_02, 28 m3, 1 compartments, fifth-wheel 1250

- Tanker SF3928.3N_01, 28 m3, 1 compartments, fifth-wheel 1250

- Chemical Tankers 96487t, 28 m3, 1 compartment, fifth-wheel 1150

- Chemical Tanker SF3920

- Tankers for chemicals transportation SF3825

- Trailers

- Tank-Containers

- Tipping Silos

- 4-axle semitrailers

- Tank Trucks

- Cesspool emptying machine

- Cryogenic tankers

- Cryogenic tank containers

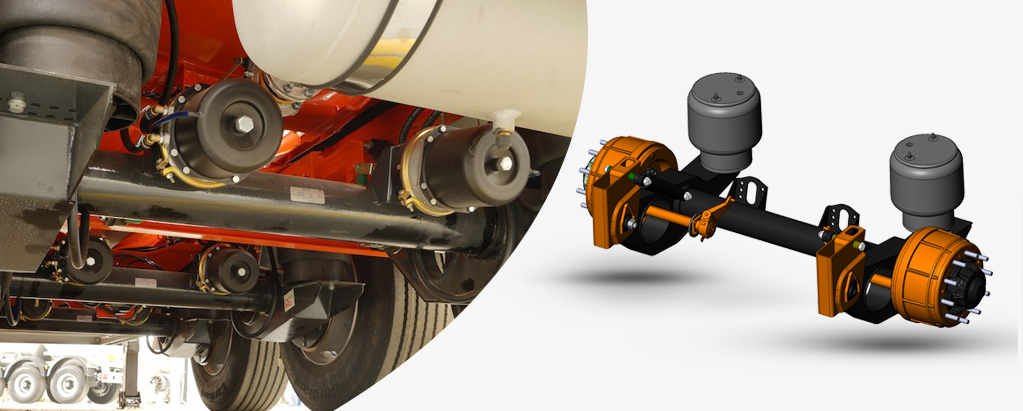

Sespel axle unit

Sespel is the leader in the production of semi-trailers for any purpose in Russia and CIS countries. Sespel products are distinguished for their high quality, reliability and focus on the needs of the market, which allows the plant to be on a leading position in the global market.

In 2018 the company expanded its production by introducing lightweight axles for the entire line of Sespel trailers and semi-trailers designed to solve a wide range of tasks. The axles are a concept of carefully assembled high-quality components. Axle, bearings, brakes and brake discs, shock absorbers and air springs are not only made with the highest quality, but also perfectly match each other and brilliantly cope with the task.

| Basic parameters | Values |

|---|---|

| Length, mm | 2280 |

| Width, mm | 1210 |

| Axle weight, kg | 500 ± 2% |

| Maximum permissible static load on the axle, kg | 9000 |

| Number of wheel on the axle, pcs. | 2 |

| Wheel track, mm | 2040 |

| Tyre size | 385/65 |

| Wheel type | R 22.5 |

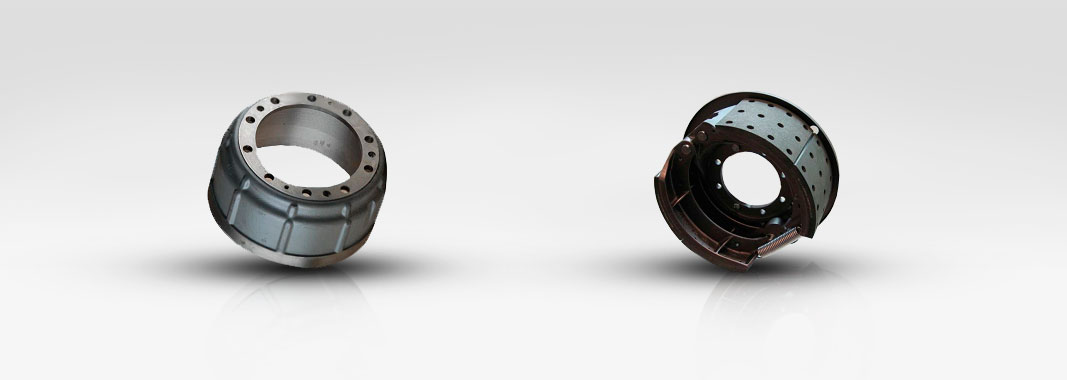

| Brake drums diameter, mm | 420 |

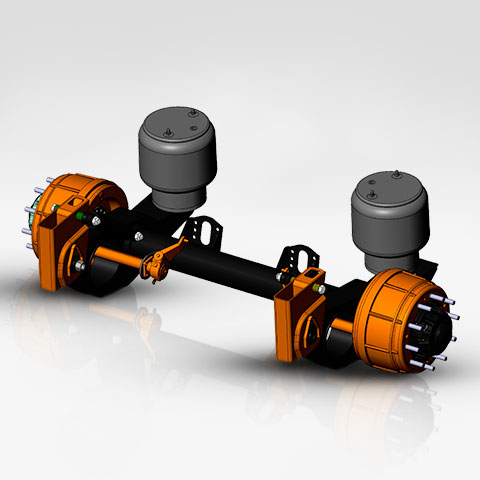

Inside the brake drum on the brake calipers there are brake shoes on which the pads are fastened with rivets. A brake camshaft passes through a hole in the brake caliper, at the other end of which a worm-type adjusting lever is installed, which is connected to the brake cylinder rod.

A reliable compact axle beam is a high-alloy steel circular pipe with welded wheel ends. The axle beam design combines a trailing arm, an axle tube, a brake caliper flange and a wheel end, which together make up a perfect device. The uniform distribution of forces in high-loaded areas of the structure ensures its long service life.

-

Wheel end

Wheel endThe forged wheel end is an important element of the axle structure, which is attached to the axle beam by friction welding. It is in direct contact with the cassette-type bearings and takes up the entire load from them. The wheel end has high strength characteristics, increased wear resistance and is not subject to corrosion.

-

Cassette-type bearing

Cassette-type bearingIt is a double-row tapered bearing, adjusted by gaps, lubricated and sealed to prevent penetration of water, dust and dirt inside the bearing. Maintenance is not required through the use of advanced technologies.

-

Hub

HubThe reliable hub design for mounting wheels with 22.5 inches radius. The hub is fixed with a bearing nut, locking washer, retaining washer and locking nut. The brake drum is attached to the hub with the help of studs, which at the same time serve as wheel disсs fastening.

-

Brake chamber

Brake chamberA bracket for brake chamber installation is welded on the axle beam. It is intended for actuation of the brake mechanism (brake drum).

Sespel axles are the optimal solution for trailers with the load up to 9 tons per axle and a wide range of ground clearance. It is suitable for driving on and off-road and is compatible with the wheel type R 22.5. The axles are manufactured in climatic version “У”, according to customer requirements they can be made in “ХЛ” and “T” versions, which must be stipulated by the consumer in the supply agreement.

The axle units are manufactured in compliance with design requirements TU 29.32.30- 054-05444977-2017, design documentation approved in accordance with the established procedure TR TS 018/2011, GOST 14650-6б this ensures reliability and safety while using Sespel axles.

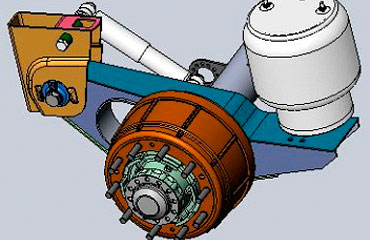

A semi-spring is a welded structure that forms a solid one-piece connection and serves to connect a stabilizing shock absorber and an axle beam. Also, on the semi-spring there installed: a bracket, an air bag and a bushing (silentblock).

The stabilizing shock absorber undertakes function of stabilizing and damping while driving straight and turning, suppresses high-frequency vibration. Built-in springs guarantee stable straight movement. When turning, the built-in springs of the shock absorber compensate the lateral force and ensure shock-free movement when the wheels return to the “strictly straight” position.

-

Suspension bracket

Suspension bracketA bracket is a welded structure and it serves as a connecting link between the vehicle frame and semi-spring.

-

Air bag

Air bagThe air bag is the main elastic element of the air suspension. The role of an elastic body performs compressed air. The air bag cover consists of several layers of rubberized fabric (carcass), an outer protective and internal sealing. The airbag is designed to suppress high-frequency vibration and ensure stable straight movement.

-

ABS sensor

ABS sensorThe axle structure provides a system for preserving the vehicle stability and steerability (ABS).

Most of our customers choose Sespel chassis of our own production. First of all, this is due to the fact that we are responsible for the entire semi-trailer, and we guarantee proper and reliable operation of all its parts, assemblies and mechanisms. And a wide network of service centers located throughout Russia and the CIS countries provides fast maintenance service of Sespel vehicles.